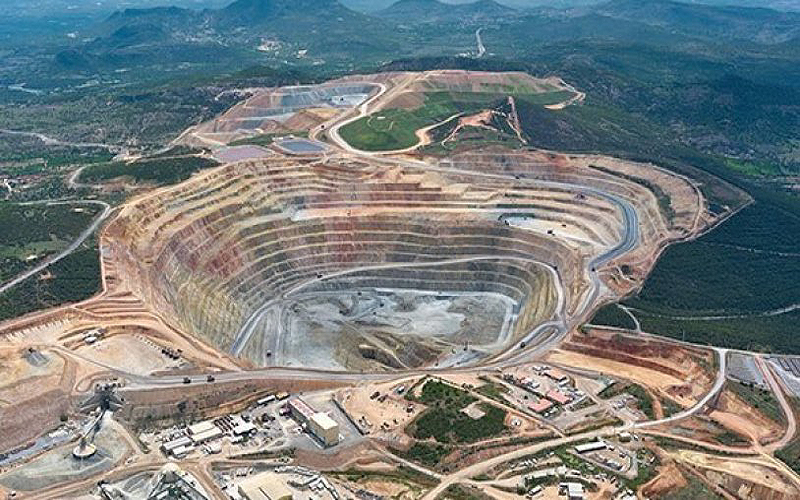

Case Studies for Mine

Water Treatment Systems

Responsibly execute water treatment and protect the environment while maintaining high levels of productivity.

Responsibly execute water treatment and protect the environment while maintaining high levels of productivity.

Provided treatment program design and implementation guidance for the process plant water treatment (antiscalant) program. Developed and implemented service and performance monitoring programs and assisted with program optimization. Services are

ongoing

Providing technical assistance with optimization of autoclave operations and overall recovery improvements including optimization of sulfide flotation, organic carbon depression, autoclave chemistry, CCD circuit efficiency and CIL recovery.

Provided detailed water chemistry modeling and sulphate and calcium balances across all unit processes to better understand the scale formation tendencies in the process water circuits. Provided updated inhibitor chemistry and treatment program to control severe scale formation in the water systems.

Provided audit services for the process plant water treatment (antiscalant) program. Generated a report that was used to initiate process changes to minimize scale and deposition in the process water circuit and provided full specifications for the scale control program and associated service program.

Acting as part of the owner's team provided process water modeling to support the feasibility of dry stack tails and a closed mill process water loop. Provided guidance and technical assistance with conceptual design and the contact water treatment plant. Participated in a variety of activities as the owner's team water treatment and chemistry specialist.

Acting as part of the owner's team to specify and procure a pilot membrane treatment plant for proof of concept testing of tailings storage facility reclaim water.

Provided conceptual design and water quality modeling for an American mine development to meet very strict environmental discharge regulations. Provided a detailed water treatment plan report to support permitting for the mine development.

Provided design, commissioning and operations support for a 140 M3/hr ultrafiltration/reverse osmosis plant to treat tailings water for discharge to the environment. Start up included in situ cyanide destruction utilizing a modified operational configuration for the UFRO plant.

Provided technical support with respect to specialty chemical applications in the mining industry. Trained salesforce on technical aspects of mining and mineral processing.

Provided design, equipment sourcing, and costing for a temporary water treatment system for feedwater to the AARL elution circuit. Improved water quality was required to meet water specifications for performance guarantee.

Provided predictive water chemistry modeling for a proposed base metals operation in Eastern Europe. Modeled expected process water chemistry based on raw water quality and reagent suite to support the operability of a dry stack tails system and closed process water loop.

Provide ongoing technical and sales support for mining industry customers and prospects of this Turkish water treatment company. Services include training of personnel, technical field support, product development assistance, and treatment systems and program development assistance.